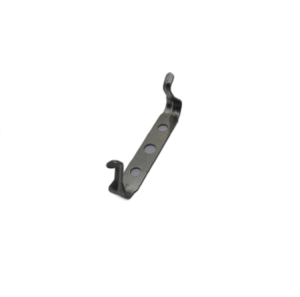

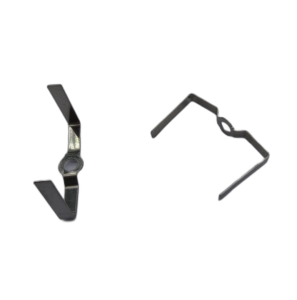

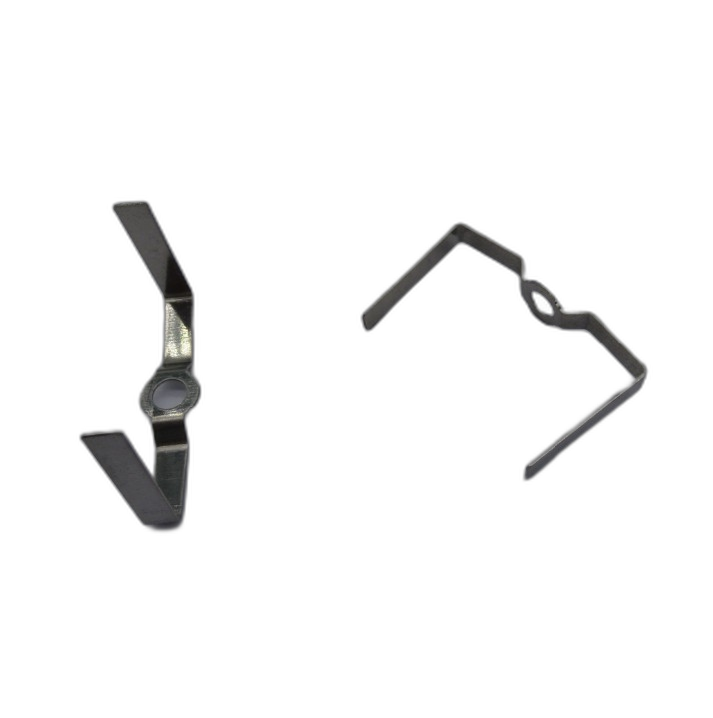

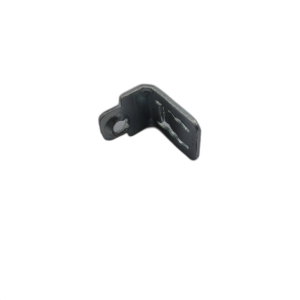

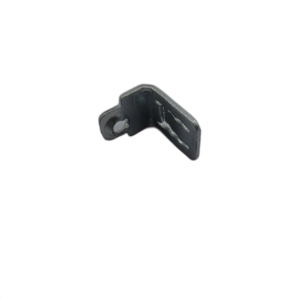

Material: stainless steel such as 304 or other grades;

Quality Key Points: Dimensions and Completion

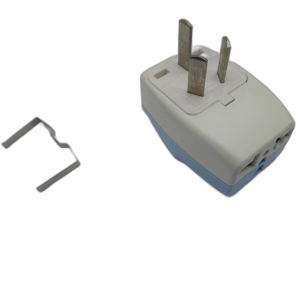

Specifications: The socket is used in 0.8mm. For electronic products, it depends on the designer and actual usage;

application:

Sockets, switches and plastic fasteners are combined together;

Quality Control:

The hardness of the raw material is a critical step. The hardness of the raw material should be confirmed before production. If the hardness is not what the drawing allows, the shape of the complete metal part can vary greatly.

Material properties:

Regarding character, it is more demanding on the surface. Sometimes, it should be polished from raw materials. Sometimes, the finished product of the raw material is matt.

FAQ :

Why is the progressive die of stainless steel parts so high? This is due to material properties. To make this material, the die iron will be cut bit by bit. We also failed to increase production speed. Stainless steel has good strength. When we take shape, we have more steps. For normal molds for iron, it only takes 2 steps. For stainless steel parts, 5-6 finishing steps are required. In this case, we can ensure that the dimensions are 100% matching the drawing.

How fast are stainless steel parts produced? It’s about 100 times per minute. Everything depends on the product and mold design. If the metal part is threaded, the speed will be lower, only 60 per minute. If it requires higher speed, the thread will not run smoothly.

-

Metal stampings for socket switch done with pro...

-

Lathe metal part socket parts Steel/Brass clamp...

-

Metal copper stampings Electrical parts for soc...

-

Electric Socket Switches Sheet customized Brass...

-

Electrical Connection Box Plastic Injuntion Box...

-

Customized Precision Metal parts of wiring dev...