Plastic Injection Molding - Connector box plastic precision electronic parts injection mold – S.W ELECTRIC Detail:

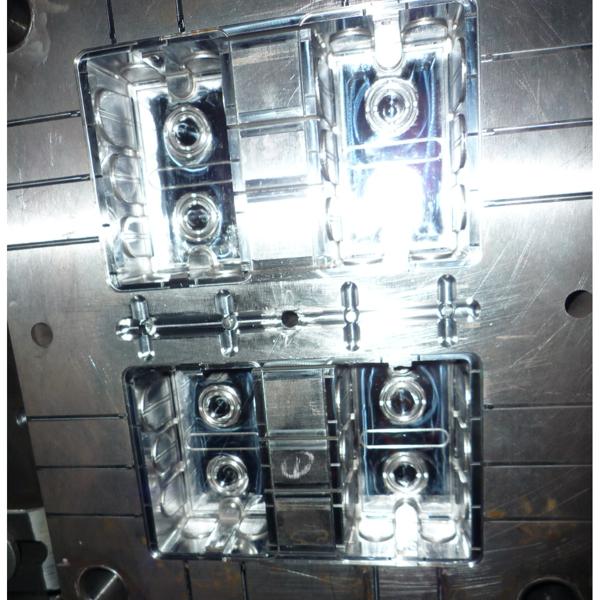

Mould material: H13 ,S136, 718H , 1.2836 .P20

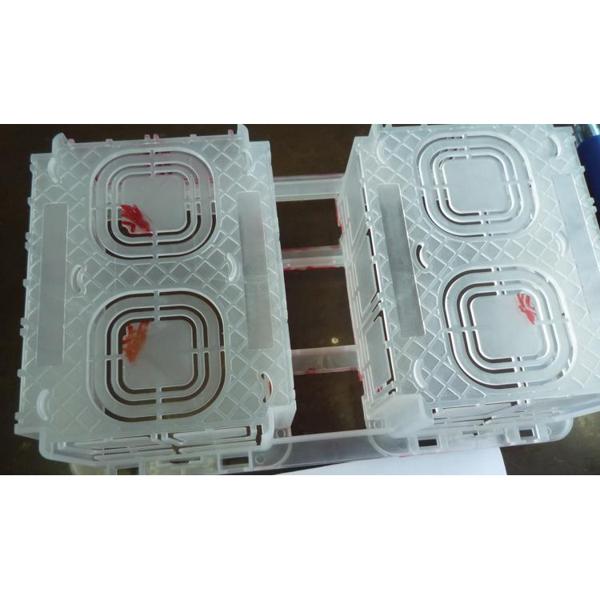

Key points of product quality: Most of the materials of ABS and PC are used for wiring devices. The surface must have a good gloss

Short Description: Beautiful, well-constructed, with minimal sliding parts. For these projects, usually it comes with repeating stencils. The new mold should be improved on the basis of the old mold. From cooling system to finishing

Additional remarks besides quality:

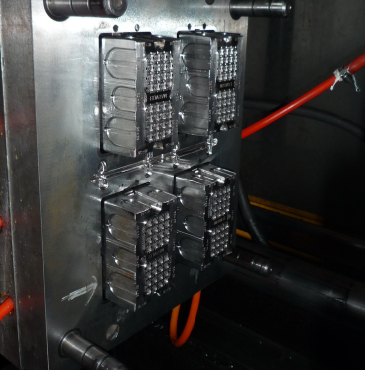

More cavities for injection molding machines

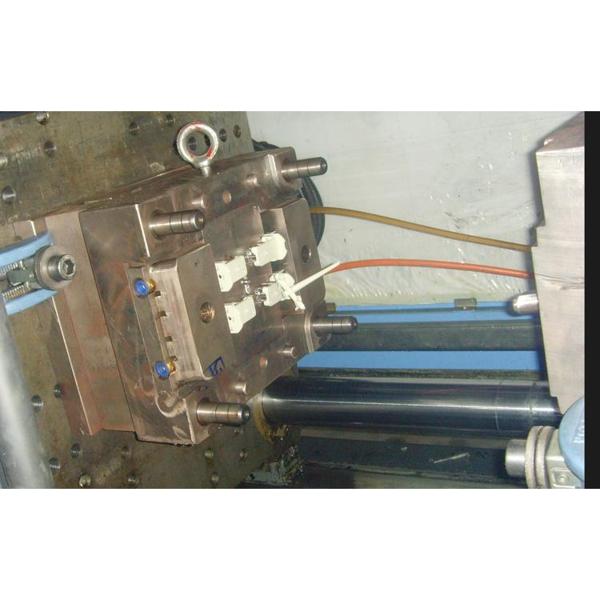

design :Consider the working state of all matching components. For dimensions, it must fit both new mold and old mold products.

Mold details:For the cooling system, each group should have its dependencies. For the sliding part, we have to make sure that the pin and ejector are back in their original position. It should add new systems to ensure this. No need for worker care.

Possible mold parts: washers, ejectors, and small slides

FAQ :

Do you have an after sales service team to support our local operations? Until now, we haven’t. As a precision injection mold, everything is stable and fixed. Just follow our manual. I will also give you the full set of drawings and possible spare parts. Due to cost control, we do not have 100% HASCCO, DME part, if you need, we can also do it.

Can you support us in repairing old molds from other manufacturers? Yes, we can do it. But we should have full information about it, also please provide a video of it in real working condition. Sometimes it is due to the mold structure. It needs big work.

Product detail pictures:

Related Product Guide:

It really is our obligation to satisfy your requirements and efficiently serve you. Your fulfillment is our greatest reward. We're hunting forward to your check out for joint development for Plastic Injection Molding - Connector box plastic precision electronic parts injection mold – S.W ELECTRIC, The product will supply to all over the world, such as: Angola, Suriname, Portland, Our mission is to deliver consistently superior value to our customers and their clients. This commitment permeates everything we do, driving us to continuously develop and improve our products and the processes to fulfill your needs.

As a veteran of this industry, we can say that the company can be a leader in the industry, select them is right.