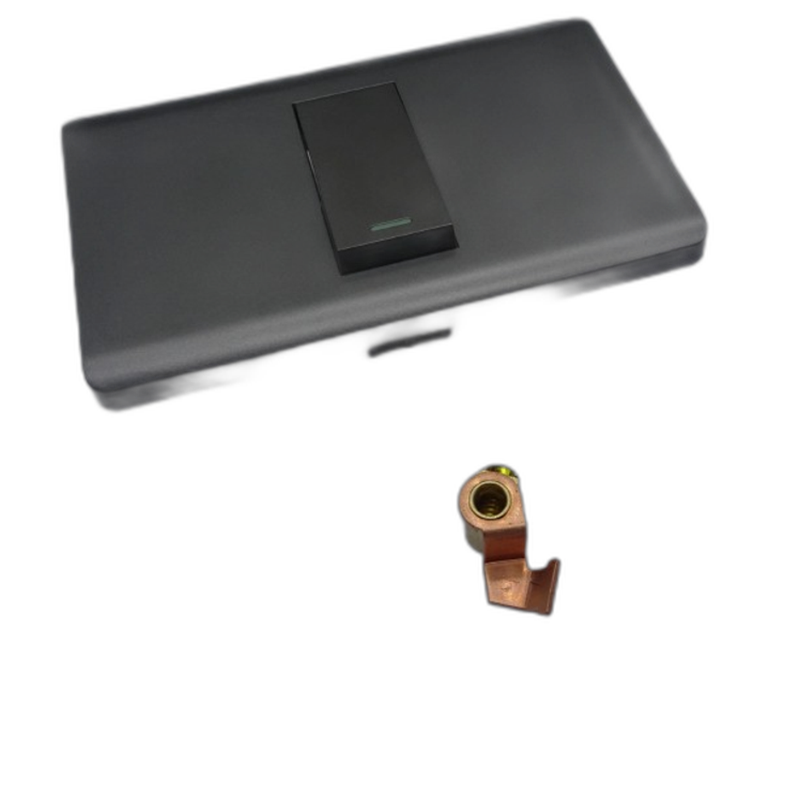

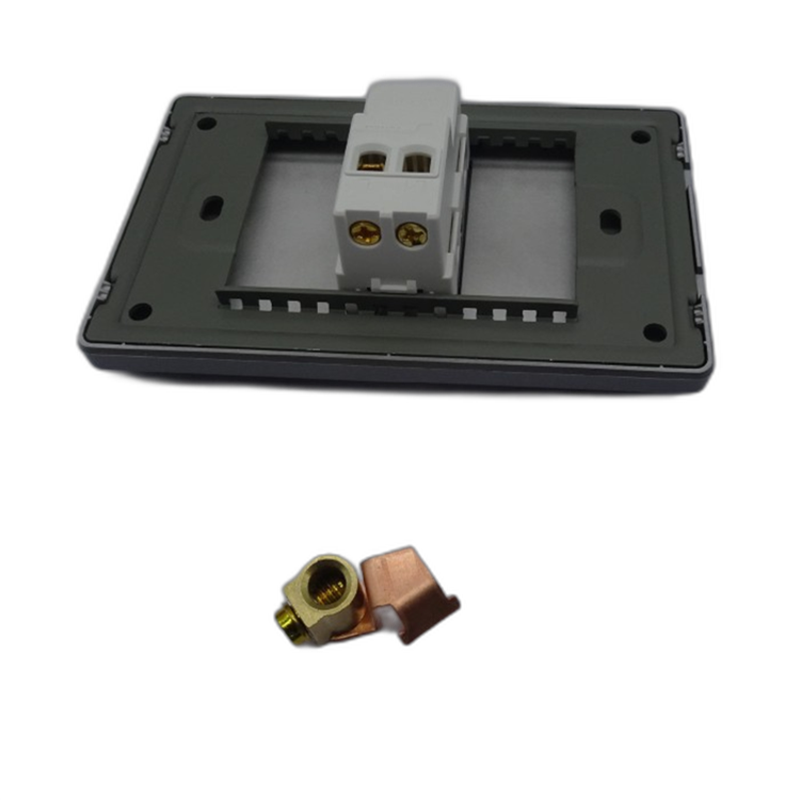

Good Quality Brass Terminal Blocks - Phosphorescent stamping – S.W ELECTRIC Detail:

Quality key points: material grade and hardness, molding tolerances

The drawing is located at the extension dxf ,dwg . or igs, step in the file.

Specification: Thickness in 1.2mm. concerning. DP switch, the material should be 1.5mm, or some silver inlay. For this treatment, the cost will be higher. If the cost is controlled, the finished product is tinned accordingly. Raw material condition: It will be rolled or flake.

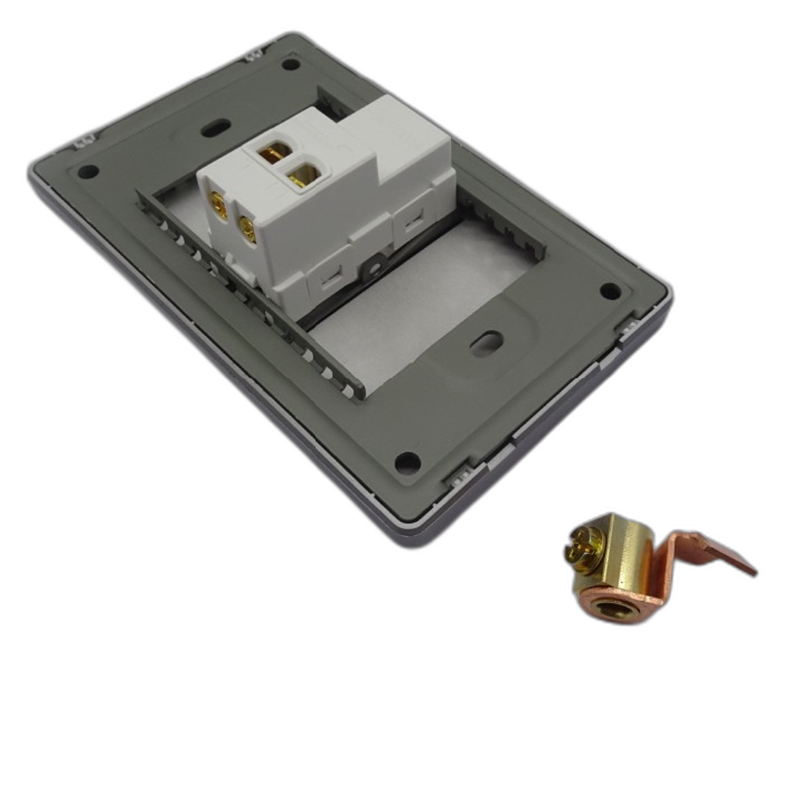

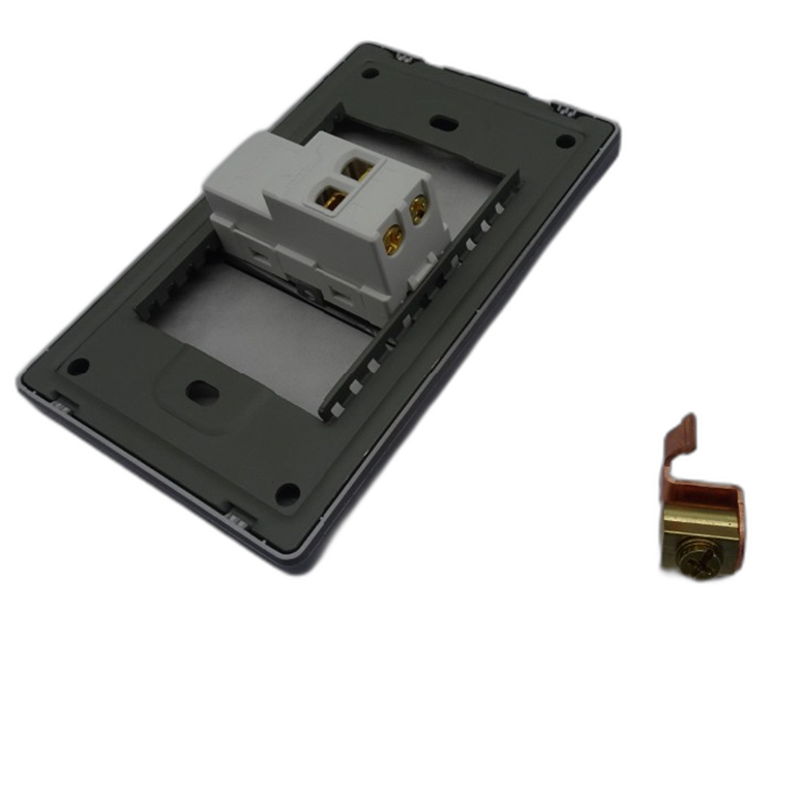

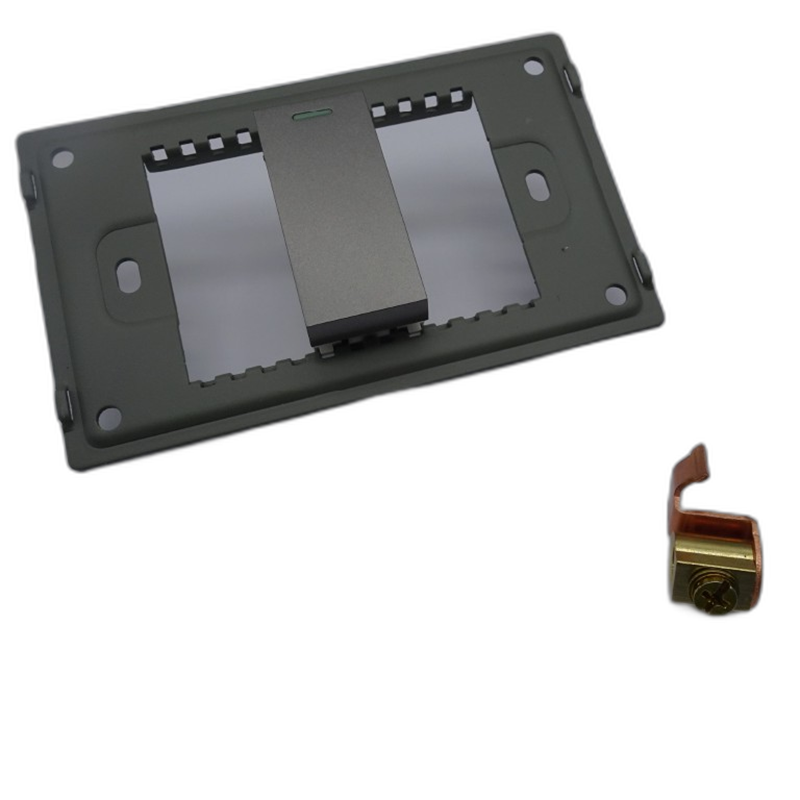

Application: DP SWITCH: Product design for this material. More than 10,000 life tests can be guaranteed. The temperature rise can also be well controlled. The photos above are for design and shape only.

For electric fields, how should we improve the electrical characteristics? We can obtain phosphorescent materials from the design. This material is also recommended for some connecting areas. Because it will improve the touch state. They can reduce the resistance, but the difference between the two parts is very small. For this material, if it is welded with silver, the surface should be treated well and cleaned. And the silver contacts will weld well on it. Electrical characteristics will take to the next level.

In actual production, how to use phosphor materials to make metal parts? The punching machine is large, the speed is slow, and the key is the progressive die. In general, if they are used in electronics, finishing must be fring-free, burr and dimensional tolerances strictly controlled according to drawings and designs.

How about the working life for tooling to make the metal parts / stamping part ? As the inside part is design as insertable . If some finishing is with metal flash , we have to replace new one . There is no relation with working life of tooling .

Product detail pictures:

Related Product Guide:

The consumer fulfillment is our primary goal. We uphold a consistent level of professionalism, top quality, credibility and service for Good Quality Brass Terminal Blocks - Phosphorescent stamping – S.W ELECTRIC, The product will supply to all over the world, such as: Ukraine, Kenya, Maldives, After years of development, we have formed strong ability in new product development and strict quality control system to ensure excellent quality and service. With the support of many long term cooperated customers, our products are welcomed all over the world.

The company account manager has a wealth of industry knowledge and experience, he could provide appropriate program according our needs and speak English fluently.