Electrical Appliance Injection Mold - Switch precision injection mold plastic parts mold die maker – S.W ELECTRIC Detail:

Mould material: S136, H13

Key points of quality: size control, spare parts finished product grade, design matching situation

Quality :Stability and working life, easy maintenance

Quality Control:All parts are from design materials. Dimensions are also 100% complete as per drawin

The assembly of the mold should be done little by little, not extensive. .

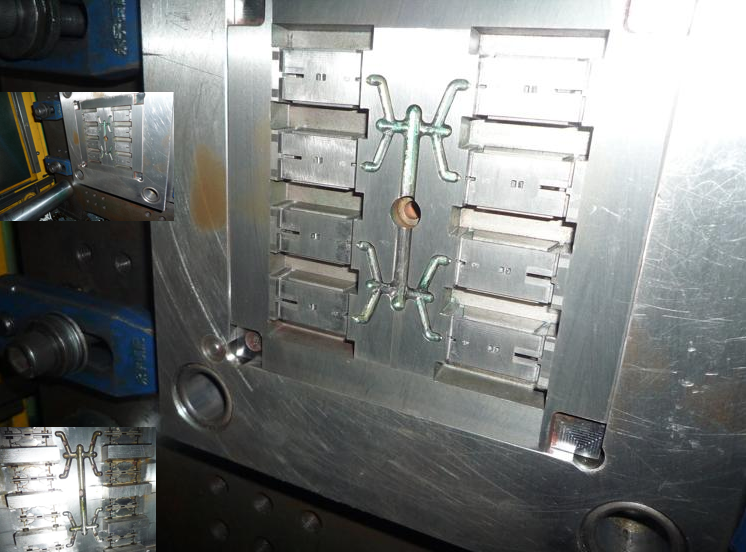

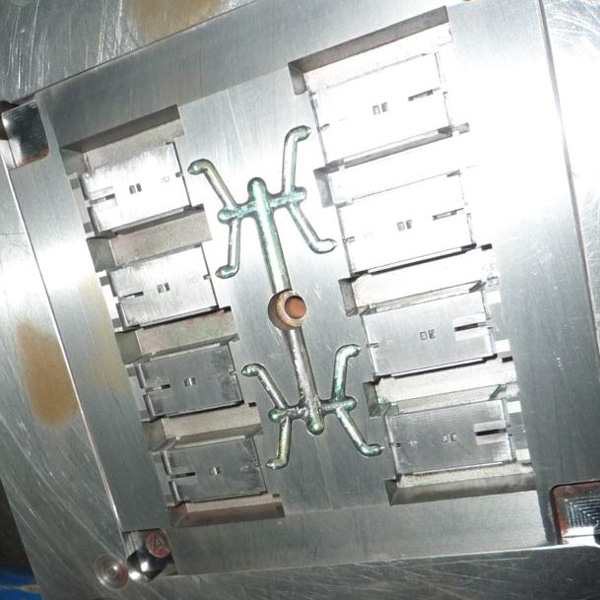

Mold details:8-cavity switch bracket mold, the mold is designed for cold runner, and the injection material is PC. The injection time for a complete cycle is approximately 25 seconds.

The key point of finishing, the injection point should be small, and the mold is designed to run fully automatically.

Mold structure: normal upper and lower molds, no sliding through new improvements in product design.

Injection molding machine size: 1200KN. Since this product is an internal matching part for the switch. So our surfaces are in a matt state, rather than polished to keep costs down.

Robot support is not required for this project. We just separate the waste from the product itself.Possible mold accessories: normal size ejector

The product itself:

Good mold, good product. Because there are a lot of plastics working together. For the size of this plastic part, it can be controlled within a dimensional tolerance of 0.05mm.

About injection molding materials. We can turn it into ABS at a lower cost. When using ABS material for injection molding, there are small tips on the plastic surface.

Since it’s more cavities, the weight is similar after we improve the injection gate point.

Product detail pictures:

Related Product Guide:

Sticking to your belief of "Creating solutions of high quality and generating buddies with people from all around the world", we always put the fascination of customers to start with for Electrical Appliance Injection Mold - Switch precision injection mold plastic parts mold die maker – S.W ELECTRIC, The product will supply to all over the world, such as: Lebanon, Finland, Italy, To let customers be more confident in us and get the most comfortable service, we run our company with honesty, sincerity and best quality . We firmly believe that it is our pleasure to help customers to run their business more successfully, and that our professional advice and service can lead to more suitable choice for the customers.

We always believe that the details decides the company's product quality, in this respect, the company conform our requirements and the goods are meet our expectations.